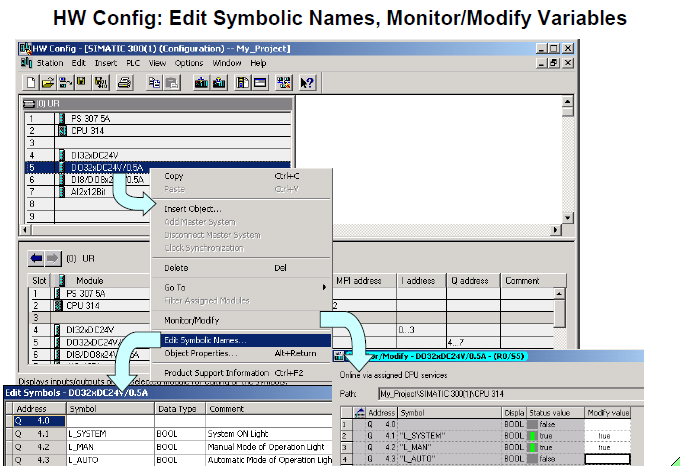

Edit Symbolic Names

You can directly access the symbol table from the "HW Config" tool. This allows

you to assign symbolic names to the inputs and outputs during hardware

configuration or at a later date when you can make suppliments or changes.

You open the symbol table with a right mouse click on the module. Select Edit

Symbolic Names in the follow-up box. A section of the symbol table with the

relevant addresses is then opened.

Monitor/Modify Variables

You can monitor or modify the addresses of the configured modules directly from the HW Config tool. The signals of the input modules can be "checked" and

the signals of the output modules can be "controlled" using the Monitor/Modify

(Variables) function.

Product Support Information

Directly from the Internet, you can fetch information on modules or components from the Product Support pages. As well, it is also possible to update HW Config

by incorporating individual components such as new CPUs or new DP devices

into the current STEP 7 version.

Requirements:

The PG/PC has an Internet connection, a browser for displaying Internet pages,

and the function is enabled in the HW Config Settings along with the

specification of the Internet address.

Note

"Symbolic Addressing" and the editing of symbol tables is dealt with in depth in

the "Symbols" chapter. The Monitor / Modify Variables function is dealt with in

the "Troubleshooting" chapter.

CPU Propertires: Cycle / Clock Memory

Cycle

• "Scan cycle monitoring time (ms):"

- If this time is exceeded, the CPU goes into the STOP mode.

Possible causes why this time is exceeded: communications processes,

frequently from interrupt events, errors in the CPU program.

- If you have programmed an error OB 80, the scan cycle time is doubled.

After that, the CPU also goes into the STOP mode.

• "Cycle load from communication (%):"

- Communication (such as data transmission to another CPU through MPI

or test functions the PG/PC triggered) is restricted to the specified

percentage of the current scan cycle time.

- Restricting the cycle load can slow down communication between the

CPU and PG.

- Example: Restricting communication to 20% results in a maximum

communication load of 20ms for a scan cycle time of 100ms.

Size of the Process Image

With the CPU 318-2 and several S7-400 CPUs, you can specify the size of the process image (in bytes). The process image area always begins with input

and output byte 0.

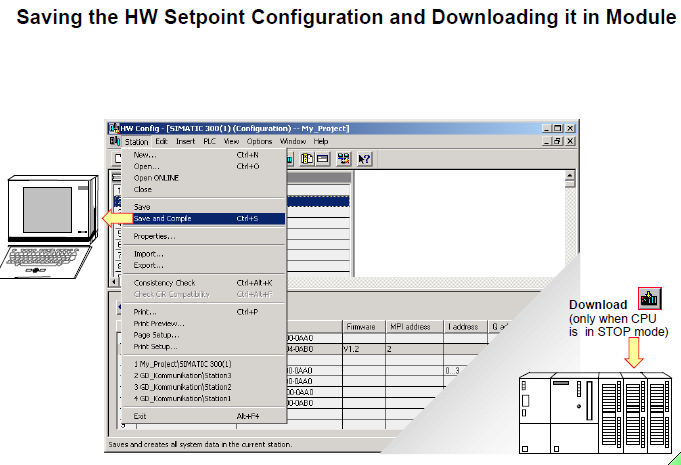

Saving the HW Setpoint Configuration and Downloading it in Module

Save

You select the Station->Save menu to save the current configuration in the

current project (without generating system data blocks).

Save and Compile

When you select the Station->Save and Compile menu or click the

icon on the toolbar, the configuration and parameter assignment data are

also saved in system data blocks.

Consistency Check

You select the Station -> Consistency Check menu to check whether it is

possible to generate configuration data from the entries made.

Download in Module

You select the PLC -> Download menu or click the icon in the toolbar to

download the selected configuration to the PLC.

The PLC must be in "STOP" mode!

System Data Blocks

The system data blocks (SDBs) are generated and modified when you configure

the hardware and compile the hardware configuration. SDBs contain

configuration data and module parameters. When a system data block is

downloaded, it is stored in the CPU‘s work memory.

This makes it easier to replace modules, because the parameter assignment

data is downloaded to the new module from the system data blocks on startup.

In the programming device, the system data blocks are saved under: Project \

Station \ CPU \ S7_program \ Blocks \ System_data.

You double-click the System data briefcase icon to see the list of system

data blocks.

If you use a memory card as Flash EPROM, you should save the SDBs there as

well. That way, the configuration is not lost if you operate without battery backup

and there is a power failure.

Upload Actual Configuration to the PG/PC and Rename It

Task

To upload a PLC‘s hardware configuration. Since the project called "My_Project"

does not yet have a HW Station, you are to read out the actual PLC

configuration from your training area. Rename the newly created hardware

station in the project "My_Station".

What To Do

• Start the SIMATIC Manager and open your project called "My_Project"

• Load the actual configuration from your training area into your project;

in SIMATIC Manager -> highlight My_Project -> PLC menu -> Upload

Station -> OK

Complete the follow-up dialog box as shown in the slide above. If no

"Accessible Nodes" are visible, you must click "Update".

• Rename the newly created "SIMATIC 300(1)" hardware station

"My_Station"

Click twice on "SIMATIC 300(1)" (not a double-click !) and type

"My_Station"

Result

In your project called "My_Project" you now have a hardware station called

"My_Station" and the hardware-independent program called "My_Program" (see

bottom picture of slide).

Adapting the ACTUAL Configuration

Task

The ACTUAL configuration read out with "Upload Station" is incomplete

because several module order numbers are missing. These numbers are

necessary to clearly identify and assign parameters to the modules. You are to

enter the order numbers of the modules of your training area (located on the

bottom, outside module cover) in the uploaded "actual configuration".

What To Do

1. Start the HW Config tool

SIMATIC Manager (Offline view) -> select HW Station called "My_Station"

-> double-click "Hardware" icon

2. Update the modules with correct order numbers

double-click each signal module -> in the dialog box "Specify Module",

choose the correct part number for the modules on your training area ->

confirm the follow-up "Properties" dialog box with OK (since the preset

standard parameters do not have to be changed).

3. Only if your training unit is an S7-400:

Specify the module addresses so that they correspond to those of an

S7-300 training unit with 32 channel modules (see slide)

double-click on Module -> specify the address in the Properties dialog box

4. Save and compile the adapted ACTUAL configuration

Station -> Save and Compile

5. Download the adapted ACTUAL configuration to the CPU

PLC -> Download

6. Exit the HW Config tool

Result

The hardware station called "My_Station" in your project called "My_Project"

corresponds to the main rack of your training unit.